Service & Solutions

One of the products MetSolv is currently using is GCAS. GCAS Brochure

What is GCAS?

GCAS® (Gas Chromatography Analysis Software) is a software tool specifically designed for gas chromatographs (GC) conditional-based monitoring. The main purpose of the monitoring embedded in the software is:

GCAS® (Gas Chromatography Analysis Software) is a software tool specifically designed for gas chromatographs (GC) conditional-based monitoring. The main purpose of the monitoring embedded in the software is:

1. To analyse instantaneous GC data and to provide a live uncertainty to see if it is operating within its stated accuracy.

2. To provide and analyse historical data in order to identify changes and predict failures.

3. To support extended reproducibility tests so that the GC uncertainty may be determined.

4. Identifies errors and self-troubleshoots to advice on the best corrective action to rectify the error and reduce prolonged financial exposure.

5. Removes the need for conventional GC maintenance activities.

What can GCAS Detect?

GCAS validates the gas chromatographs performance by detecting:

- Calibration Gas Errors

- Gas Chromatograph Leakage

- Column Deterioration

- Valve Timing Issues

- Poor Handling Procedure

- Heavy End Drop Out

- Fault in Repeatability Test Interpretation

- Fault in Control Chart Interpretation

- Fault in Composition Comparison

Live Uncertainty

With the unique patented method for calculating reproducibility GCAS is able to give you live uncertainty calculations after every routine calibration. Until recently this could only be achieved with laboratory analysis.

For fiscal applications GCAS can apply these values to ISO6976, to routinely calculate representative uncertainties for Calorific Value, Molecular Weight, Wobbe Index, Relative and Standard Density.

Supported Gas Chromatograph Brands

GCAS is compatible with any gas chromatograph device using thermoconductivity detector (TCD) and peak area formula to calculate response factor. GCAS supports the below gas chromatographs:

1. Brand-specific:

a. Daniel (Emerson)

b. ABB

c. Siemens

d. Elster (Honeywell)

2. Non brand-specific:

a. LNG chromatographs (Liquid Natural Gas, up to pentane)

b. BTEX analysers (aromatic hydrocarbons)

c. Single gas analysers

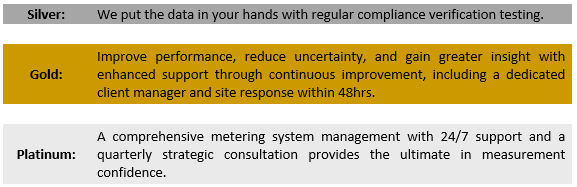

Your business can choose from three (3) customisable Support Plans designed to deliver Peace of Mind, Accuracy and Compliance.

The inclusions are found here, contact us to find more out about our Silver, Gold and Platinum packages.

Metering Support Management (MSM) Plans

| Managed Support |

|---|

| Flow Metering Skid (inc Quarterly AVT's |

| Monthly Diagnostics Monitoring Report |

| Gas Chromatograph Condition Based Monitoring inc. GCAS |

| Email/Telephone Support |

| Metering Audit – Pre-Contract Engagement |

| Calibration Gas Management |

| Configuration Backup Management |

| Spare Parts & Interchangeability List |

| Dedicated Site Technicians |

| Client Metering Sharepoint Dashboard |

| Metering Focal Point |

| Site Response within 48 Hour |

| Client Metering Familiarisation Training |

| Gas Chromatograph Routine Maintenance |

| 24/7 Support |

| Managed Advisory (Quarterly Consulting & Planning) |

| Measurement System Management |

| Measurement Manual (Scheme) |

| System Uncertainty Analysis Calculation |

| Verification Procedures |

| Calibration Certificate Management |

| Equipment Configuration Manual |

| Testing Tolerance Manual |

| Equipment Log Books |

| Mis-Measurement Management |

| Dispensation Management |

| Reporting |

| Annual Measurement Reports |

| Coverage |

| After Hours Support |

| Australia Wide On-Site Support |

| Training |

| Theoretical Metering Training |

| Practical On Site Metering Training |

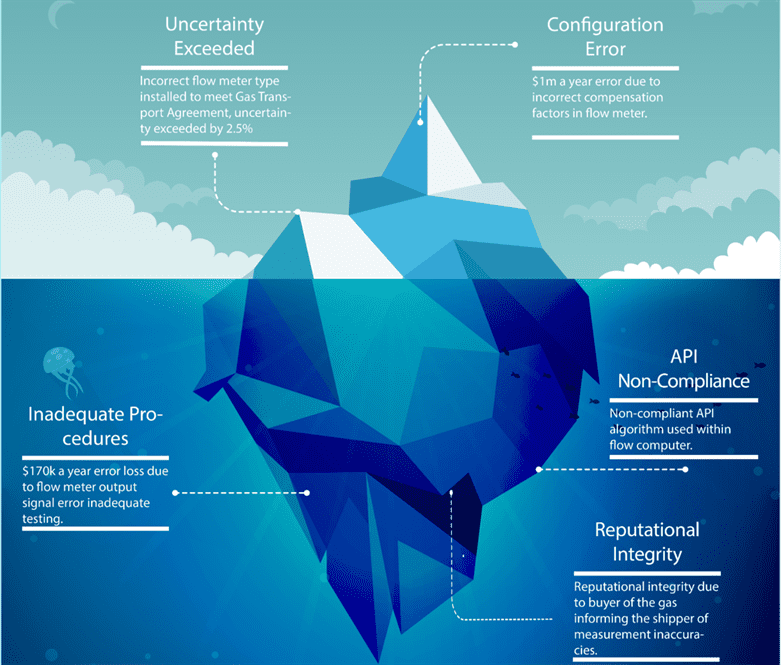

How Healthy is Your Metering System?

Ask yourself… are you sure your metering system is accurate? Is it meeting your compliance and contractual requirements? Are measurement uncertainty limits being met? Do you have measurement imbalance, or worse - equipment failure?

Complex systems require expert verification and management to ensure that compliance is continually measured and captured. MetSolv unites industry expertise with precision instrumentation technology to deliver a complete solution for the management of metering certification and operation.

We are the only Australian flow measurement consultancy company to attain the internationally recognised ISO 17020 Type-A Accreditation under the National Association of Testing Authorities. The rigour of this accreditation underscores MetSolv’s commitment to quality and service excellence.

Experts in Complete Measurement Solutions

At MetSolv, we believe continuous measurement and concise reporting provides the competitive advantage to reduce risk, provide certainty, increase efficiency and ultimately - drive profitability.

Our Metering System Plans are designed to deliver confidence in measurement quality. We remove uncertainty and streamline reporting so you can rest assured that your measurement systems are operating as accurately as possible. If you don’t have an existing measurement management system in place, we can design and implement a tailored solution that works for you. As vendor-agnostic suppliers, we always deliver the best solution for your requirements.

Metering Plans

Our plans are tailored across three levels and designed to deliver the level of support you require.

Full Managed Support List Plans

Don’t have an existing Measurement Management System?

Not a problem. The team at MetSolv can design and implement a measurement management system tailored to achieve the outcomes you need. As the overarching structure for the management of measurement for all metering stations, the MMS will incorporate statements and quality objectives to provide a clear vision and direction for the measurement.

The performance and control of the MMS provides continuous measurement improvement by continually improving standardised activities and processes.

MetSolv's Services Encompass our Metering System Lifecycle.

MetSolv's lifecycle is a view of our metering services that addresses all phases of a metering systems existence, to include system conception, design and development, production and/or construction, distribution, operation, maintenance and support, retirement, phase-out and disposal.

Customers choose MetSolv because we can provide your business with a one-stop outsourced Metering experience

SYSTEMS - DESIGN, ASSESS & CONSTRUCTION

In the initial concept stage, designers are pressed a problem they are trying to solve, and must use their engineering skills to find an effective solution. Early prototypes, even on paper, are checked against local state legislation and company metering requirements to make sure they will comply.

Initial concepts are also measured against budgetary concerns – it’s important to make metering systems that can affordably be used by companies while also maintaining the high quality standards that MetSolv is known for.

The Functional Design Specification is then taken to manufacturing, where the working device is then constructed.

The finished product is then put through a series of rigorous tests to make sure the metering system can be replicated accurately by the factory, and that it also meets the needs of the installation site.

Any errors in this process can be quickly fixed and the process starts again with a new round of testing.

SUPPORT

Now that the metering system is installed, it then starts going through its expected procedures and generating records.

It goes through correct calibration and operation procedures, and generates records such as log books and audits that can be checked later and used to process asset records or royalty payments.

MANAGEMENT

Backing up the process is MetSolv's Measurement Management System carried out by MetSolv’s experienced technicians.

To find out more about the Metering System Lifecycle and how MetSolv can help your business, contact MetSolv today.

MetSolv field support technicians will complete verification testing to establish the performance characteristics of your metering system.

Validation is the planned and documented procedure used to establish the performance characteristics of a metering system.

The validation process confirms by examining the acquired material that the particular requirements are being met and that the metering systems continue to operate within the uncertainty limits stipulated in the relevant international standards, local regulations and sales agreements.

Flow Element

Verification of a flow meter will consist of verifying that the correct and current primary meter calibration data is being applied, that the meter is operating in accordance with the relevant standard and that the fluid being measured is at appropriate conditions.

The diagnostic capability of current generation flow meters provides the operator with a flexible and powerful diagnostic capability on which to verify the meter’s performance. This information will be checked for consistency against the meter manufacturer’s data.

Flow Computer

Verification of flow computers will consist of verifying the computations performed to determine metering station through-put. The accuracy of computation is undertaken by simulating the metering stream instruments using keypad entered values for the various field inputs.

Transducers / Transmitters

Verification of secondary field transmitters will consist of verifying transmitters and associated loops to assess transmitter reproducibility performance.

Analysers

Verification of the online analysers will consist, in addition to the daily auto calibration a reproducibility and repeatability validation using a known calibration standard consisting of a gas mixture representative of the gas components found in the export gas.

Function & Feature Testing

Your equipment’s basic functions and features may be spelt out in the manual, but it is important you are aware of their strengths and limitations. MetSolv’s technicians can determine the most functional aspects of your equipment.

Contact MetSolv today to find out how one of our Australian expert Engineers or Technicians can help you to validate the functional aspects of the flow metering of your oil and gas operations.

Complex systems require expert verification and management to ensure that compliance is continually measured and captured.

Our highly skilled team deliver industry leading services following the ISO 10012 Measurement Management Systems support framework.

We provide metering compliance solutions that including on site verification, independent auditing and a comprehensive range of consultancy services.

MEASUREMENT MANAGEMENT SYSTEM

The structure for the management of measurement for all metering stations, the MMS will incorporate statements and quality objectives to provide a clear vision and direction for the measurement.

- Measurement philosophy

- Metering station classification

- Control of documentation

- Measurement processes and procedures

- Management system review

- Measurement organisational structure charts

- Measurement traceability

- Equipment Inventory

CONSULTANCY SERVICES

MetSolv's consultancy services focuses on delivering an independent and comprehensive range of flow metering services. Fully conversant in both Australian and International standards in quality and flow measurement to provide:

- Meter selection studies

- Investigation and resolution of flow measurement problems

- Creation of functional metering documentation

- System Acceptance Test and reports

- Uncertainty Studies to demonstrate that the meter station meets the contractual or regulatory uncertainty requirements

MetSolv's consultants are proactive in delivering metering management for the flow metering needs of your business. Your competitive advantage can be improved by the immediate and long-term performance of your business and the supply-chains it follows.

MetSolv appreciates that in today's competitive industries you require accurate measurement of the quantities and qualities produced to optimise process performance. These complex systems require expert validation and management to ensure that compliance is continually measured and captured.

INDEPENDENT METERING SYSTEM AUDIT

MetSolv can facilitate meter calibration requirements on your behalf and offer an independent test and calibration witnessing service. Viewing the live operation of the meter, assembly of the metering run and other calibration data in a transparent way.

TRAINING

Get a practical understanding of the key principles of flow measurement in this comprehensive one-day course on metering.

Give MetSolv a call to see how we can assist you today.

Audits are undertaken to check and validate hydrocarbon measurement instrumentation, data reporting, traceability and procedures.

It is essential that any problems, potential or actual are identified and highlighted; identification of such problems can result in financial savings. Measurement audits ensure that measurement systems are in compliance with the current regulations, international standards and commercial agreements.

Why Audit

Costly metering issues may go unnoticed during normal operations. In many cases only a very small amount of information is available or visible about a situation or phenomenon. Diligent inspections can dramatically reduce the probability of such occurrences.

MetSolv's Independent Audit

MetSolv knows that streamlining your cost of doing business is integral to your profitability. The accurate and efficient operation of metering equipment is a critical aspect of any process handling vast volumes of fluids.

An equipment and systems audit is the best way to capture and measure your metering performance.

MetSolv can deliver:

- Independent metering system audits

- System performance assessment

- Assessment of the primary measuring devices

- Thorough check of all metering system equipment and their components

- Assess the knowledge of the operator

- Review operational and maintenance procedures

The audit and inspection report will provide for you and your employees a comprehensive collection of data that is clear and concise.

- Assessment that your metering equipment is functioning within compliance standards

- List of actionable measures for improving measurement accuracy

- Recommend economical alternatives for future performance improvements

- Operation and maintenance procedures

- Operator training

- Product upgrades

Get in touch with MetSolv today to discuss how we can help you with an equipment and systems audit.